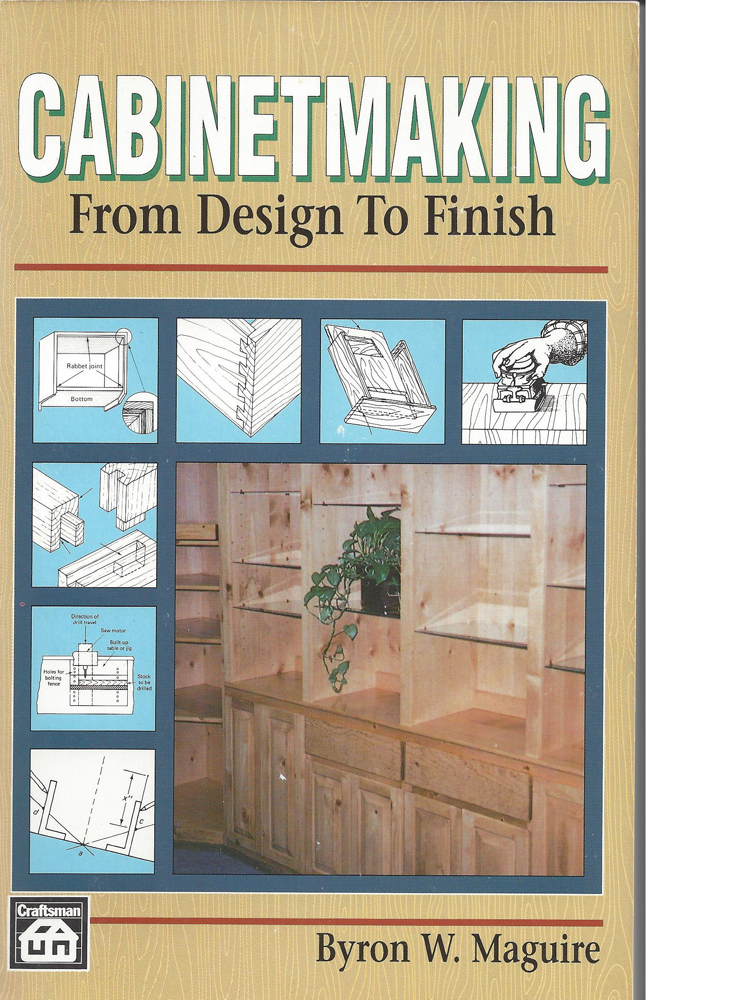

Cabinetmaking: From Design To Finish

Every aspect of cabinetmaking, from layout, through joinery, to finishing techniques. Gives illustrated instructions for designing cabinets to fit the kitchen workcenter; create dado, mortise, tenon, lap and dowel joints; make frames and panels; construct cabinets; and install cabinet hardware.

Every aspect of cabinetmaking, from layout, through joinery, to finishing techniques. Gives illustrated instructions for designing cabinets to fit the kitchen workcenter; create dado, mortise, tenon, lap and dowel joints; make frames and panels; construct cabinets; and install cabinet hardware.

| Weight | 1.100000 |

|---|---|

| ISBN | 0-934041-62-8 |

| Page Count | 416 |

| Author | Byron W. Maguire |

| Publisher | Craftsman Book Company |

| Dimensions | 5-1/2 x 8-1/2 |

Contents

UNIT I, 1

- 1. Features of Cabinets and Furniture, 3

- 1.1 How to Build the Cabinet with a Purpose, 4

- 1.2 How to Coordinate the Cabinet with Other Furniture, 6

- 1.3 Furniture Styles, 12

- Questions, 25

- Project, 26

- 1.2 How to Coordinate the Cabinet with Other Furniture, 6

- 2. Kitchen Designing and Cabinet Making Techniques, 27

- 2.1 Introduction, 27

- 2.2 Designing the Kitchen, 28

- 2.3 Positioning the Centers and Large Appliances, 46

- 2.4 Specifications of Cabinets, 51

- 2.5 Source of Cabinet Building Supplies, 54

- 2.6 Closing Comments, 57

- Questions, 58

- Project, 58

- 2.2 Designing the Kitchen, 28

- 3. Shapes and Accents, 59

- 3.1 Basic Shapes of Cabinets, 60

- 3.2 Framing Square, 62

- 3.3 How to Make a Square Layout, 63

- 3.4 How to Make a Rectangular Layout, 66

- 3.5 How to Make a Triangle Layout, 69

- 3.6 How to Make a Diamond-Shaped Layout, 70

- 3.7 How to Make an Octagon Layout, 71

- 3.8 How to Make a Circle, 74

- 3.9 How to Make a Hexagon Layout, 76

- 3.10 How to Make an Ellipse, 81

- 3.11 How to Make a Polygon, 83

- 3.12 Molding, 84

- Questions, 90

- Project, 92

- 3.2 Framing Square, 62

UNIT II, 93

- 4. How To Make A Butt Joint, 95

- 4.1 Functional Qualities and Applications, 96

- 4.2 Design Effects Created by Use of the Butt Joint, 98

- 4.3 Problems Solved by Use of the Butt Joint, 98

- 4.4 How to Make a Butt Joint with Hand Tools, 100

- 4.5 How to Make a Butt Joint with Portable Power Tools and Hand Tools, 102

- 4.6 How to Make a Butt Joint with Bench Power Tools, 103

- Questions, 106

- Project, 106

- 4.2 Design Effects Created by Use of the Butt Joint, 98

- 5. How to Make A Rabbet Joint, 107

- 5.1 Functional Qualities and Applications, 108

- 5.2 Problems Solved by Use of the Rabbet Joint, 110

- 5.3 How to Make a Rabbet Joint with Hand Tools, 154

- 5.4 How to Make a Rabbet Joint with Portable Electric Tools, 114

- 5.5 How to Make a Rabbet Joint with Bench Power Tools, 119

- Questions, 128

- Project, 128

- 5.2 Problems Solved by Use of the Rabbet Joint, 110

- 6. How to Make A Dado Joint, 129

- 6.1 Functional Qualities and Applications, 130

- 6.2 Problems Solved by Use of the Dado Joint, 131

- 6.3 Methods That Can Be Used to Make a Dado Joint, 134

- 6.4 How to Make a Dado Joint with Hand Tools, 135

- 6.5 How to Make a Dado Joint with Portable Power Tools, 137

- 6.6 How to Make a Dado Joint with Bench Power Tools, 141

- Questions, 145

- Project, 146

- 6.2 Problems Solved by Use of the Dado Joint, 131

- 7. How to Make A Mortise, 147

- 7.1 Functional Qualities and Applications, 149

- 7.2 Problems Solved by Use of the Mortise and Tenon Joint, 151

- 7.3 Methods That Can Be Used to Make the Mortise Joint, 152

- 7.4 How to Make a Mortise Joint with Hand Tools, 152

- 7.5 How to Make a Mortise Joint with Portable Power Tools, 156

- 7.6 How to Make a Mortise Joint with Bench Power Tools, 157

- Questions, 162

- Project, 162

- 7.2 Problems Solved by Use of the Mortise and Tenon Joint, 151

- 8. How to Make A Tenon Joint, 163

- 8.1 How to Lay Out a Tenon Joint, 163

- 8.2 Functional Qualities and Applications, 167

- 8.3 Problems Solved by Use of the Tenon Joint, 167

- 8.4 Methods That Can Be Used to Make the Tenon Joint, 168

- 8.5 How to Lay Out a Tenon Joint by Shop Methods, 168

- 8.6 How to Make a Tenon Joint with Hand Tools, 170

- 8.7 How to Make a Tenon Joint with Portable Power Tools, 174

- 8.8 How to Make a Tenon Joint with Bench Power Tools, 177

- Questions, 185

- Project, 185

- 8.2 Functional Qualities and Applications, 167

- 9. How to Make A Dowel Joint, 187

- 9.1 How to Substitute the Dowel Joint for the Mortise and Tenon Joint, 187

- 9.2 Functional Qualities and Applications, 188

- 9.3 Problems Solved by Use of the Dowel Joint, 190

- 9.4 Methods That Can Be Used to Make the Dowel Joint, 190

- 9.5 How to Make a Dowel Joint with Hand Tools, 192

- 9.6 How to Make a Dowel Joint with Electric Drill, 195

- 9.7 How to Make a Dowel Joint with Bench Power Tools, 198

- 9.8 Jig for Drilling with Radial Saw Arm, 204

- Questions, 205

- Project, 205

- Alternate Project, 205

- 9.2 Functional Qualities and Applications, 188

UNIT III, 207

- 10. How to Make A Frame and Panel, 209

- 10.1 Functional Use and Applications, 210

- 10.2 Methods That Can Be Used to Make the Frame and Panel, 210

- 10.3 Design Effects Created by Use of the Frame and Panel, 212

- 10.4 Problems Solved by Use of the Frame and Panel, 213

- 10.5 How to Make a Frame, 214

- 10.6 How to Make a Panel, 215

- Question, 225

- Project, 225

- Alternate Project, 225

- 10.2 Methods That Can Be Used to Make the Frame and Panel, 210

- 11. How to Make Lap Joints, 227

- 11.1 Functional Use and Applications, 227

- 11.2 Methods That Can Be Used to Make Lap Joints, 229

- 11.3 Design Effects Created by Use of the Lap Joint, 233

- 11.4 Problems Solved by Use of the Lap Joint, 234

- 11.5 Ways to Make the Lap Joint, 234

- Questions, 244

- Project, 245

- 11.2 Methods That Can Be Used to Make Lap Joints, 229

- 12. How to Make the Miter and Other Cuts, 247

- 12.1 Functional Use and Applications, 248

- 12.2 Methods That Can Be Used to Make the Miter Joint, 249

- 12.3 Design Effects Created by Use of the Miter, 252

- 12.4 Ways to Make the Miter, 253

- Questions, 259

- Project, 260

- 12.2 Methods That Can Be Used to Make the Miter Joint, 249

UNIT IV, 261

- 13. How to Construct A Cabinet, 263

- 13.1 How to Sketch Ideas, 265

- 13.2 How to Plan for Acquisition of Materials, 269

- 13.3 How to Cut Materials, 278

- 13.4 How to Assemble a Cabinet, 282

- Questions, 291

- 13.2 How to Plan for Acquisition of Materials, 269

- 14. How to Prepare A Cabinet or Finishing

- 14.1 Rough-to-Smooth Sanding Techniques, 295

- 14.2 Terms, 295

- 14.3 How to Select the Type of Grit for the Job, 297

- 14.4 How to Select the Backing Material for the Job, 300

- 14.5 How to Select the Method, 307

- 14.6 How to Sand the Credenza, 312

- 14.7 How to Sand for a Finish, 313

- Questions, 315

- 14.2 Terms, 295

- 15.

How to Finish A Cabinet, 317

- 15.1 How to Finish the Cabinet, 318

- 15.2 Finishing Steps, 319

- 15.3 How to Fill, 319

- 15.4 How to Seal, 322

- 15.5 How to Stain, 323

- 15.6 Undercoats and Intermediate Finish Coats, 326

- 15.7 Final Coats, 328

- 15.8 How to Complete the Finish, 329

- 15.9 Finishing Methods, 332

- Questions, 338

- 15.2 Finishing Steps, 319

UNIT V, 341

- 16. Types of Wood, 343

- 16.1 Hardwoods (Broad-Leaved Species), 343

- 16.2 Softwoods (Cone-Bearing Species), 366

- Questions, 383

- 16.2 Softwoods (Cone-Bearing Species), 366

- Appendix: Tables, 385

Glossary, 391

Index, 399

Preface

The most impelling reason for anyone to work with wood is probably the satisfaction they get from seeing the finished product. So much of our everyday work is often cloaked in mass production methods that we never see an end product created by ourselves. Each of us may perform a single step or a group of steps in a manufacturing process, and often our work is fatiguing and dull. So we look for an escape.

Woodworking often fills this need. In addition to its function as a relief valve for tension, it produces a product-lasting and often quite beautiful. By careful selection of materials and designs, the finished product takes on its beauty. It incorporates the qualities of the materials and the skill of the craftsman.

This book provides you with basic knowledge of woodworking joinery so you can increase your skill, fashion a finer product, and create furniture that is structurally sound, is functional, and has lasting quality and beauty.

The book is divided into five homogeneous units that examine parts of the woodworking field. Unit I explains, and attempts to develop an interest in, the shapes, styles, and characteristics of furniture and cabinetry. Unit II develops methods of making individual cabinet joints in a variety of ways so that those who have only hand tools can make the joints. There are also descriptions for those who have some portable tools and for those with a full or partial shop of bench tools. Unit III details and illustrates how to combine the usual joints into combination joints that ultimately go into many cabinets. Each chapter in this Unit includes full-page preferred sequence instructions and illustrations so that the book may be set on the work bench as a ready reference. Unit IV presents a methodology for cabinet construction. In hopes of making the study more meaningful, a sample project is designed, planned, assembled, and finished. Unit V is a gathering of reference data that should prove very useful. A short chapter on fine woods is presented, followed by an appendix containing tables showing screws, nails, plywood, and other common building needs, and by a glossary of terms.

I wish to express my sincere thanks to all of those persons in the industries for their assistance in providing me with data and illustrations that have made this book more meaningful.

Unit I

Unit I consists of three chapters concerned with developing a sensitivity for the beauty of fine woodworking. We start by examining cabinets and furniture, studying six major styles in detail. Chapter 2 discusses the planning and designing of a modern kitchen, with emphasis on efficiency, safety, and style. Chapter 3 then defines cabinet shapes, using shop methods rather than engineering methods. Some of the tools featured in Chapter 3 are the square, dividers, twine, and the straightedge.

Whether you're a professional builder or carpenter, or someone who enjoys working with wood simply for the pleasure of the art, you'll find this book an indispensable workbench tool. It's a ready-reference guide that will help you with any cabinetmaking project you're likely to take on. The book takes you step-by-step through the process of designing, building, and finishing most types of cabinetry, from a single credenza to a whole kitchen layout.

You'll find clear instructions and craftsman's tips on:

-

Selecting woods

-

Tools, both hand tools and power tools

-

Cabinet shapes and design

-

Making a cabinetmaker's special points and cuts

-

Applying finishes, trims and moldings

The author uses simple shop methods rather than engineering methods to teach fine woodworking and joinery. You'll learn how to design and plan a project to avoid the costly mistakes poor planning will bring, and how to build and finish pieces that will be true works of art you'll be proud to display. Dozens of drawings and photographs supplement the text and show you the end product, and a glossary of terms will help you describe your needs to the material supplier.

About the Author

Byron W. Maguire has been fascinated with woodworking since childhood. A true craftsman, he began his official training when he was twelve years old working as an apprentice to his father, who was a master cabinetmaker. While in the USAF, he spent nine years in the Civil Engineer's carpentry shop where he built furniture and cabinetry for many of the base clubs and chapels. After leaving the service, Mr. Maguire went into business remodeling kitchens and building cabinetry and specialty pieces, and taught classes in cabinetmaking at the Junior College VoTech center. He sees fine woodworking not only as a craft that produces long-lasting, beautiful pieces of furniture, but as creative artistry that offers a release from the stress of the dull, routine work most people spend their working lives doing.